2009年4月30日星期四

seed treatment

作物、林木种子播种前采用的物理、化学或生物处理措施的总称。包括精选、晒种、浸种、拌种、催芽等。目的是促使种子发芽快而整齐、幼苗生长健壮、预防病虫害和促使某些作物早熟。

精选。在种子晒干扬净后,采用粒选、筛选、风选和液选等方法精选种子。种子精选目的是消除秕粒、小粒、破粒、有病虫害的种子和各种杂物。②晒种。利用阳光曝晒种子。具有促进种子后熟和酶的活动、降低种子内抑制发芽物质含量、提高发芽率和杀菌等作用。③浸种。作用是促进种子发芽和消灭病原物。方法有:清水浸种、温汤浸种、药剂浸种。应按规程掌握药量、药液浓度和浸种时间,以免种子受药害和影响消毒效果。④拌种。将药剂、肥料和种子混合搅拌后播种,以防止病虫为害、促进发芽和幼苗健壮。方法分干拌、湿拌和种子包衣。⑤催芽。播前根据种子发芽特性,在人工控制下给以适当的水分、温度和氧气条件,促进发芽快、整齐、健壮。方法有地坑催芽、塑料薄膜浅坑催芽、草囤催芽、火坑催芽、蒸汽催芽等。此外,还有种子的硬实处理和层积处理。硬实处理是用粗砂、碎玻璃擦伤种皮厚实、坚硬的种子(如草木犀、紫云英、菠菜等种子),以利吸水发芽。层积处理是需后熟的种子,于冬季用湿沙和种子叠积,在0~5℃低温下1~3个月,以促使通过休眠期,春播后发芽整齐。

拌种

在播种前将种子与农药、菌肥等拌和。农药防止病虫害,菌肥作为种肥或接种剂。

对豆科作物进行根瘤菌拌种是提高豆科作物产量的一项有效措施.

2009年4月28日星期二

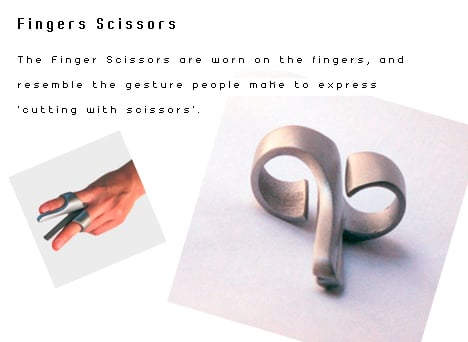

Keep on Finger Snippin

Cut! It! Out! You’ve got to be kidding me, girl! These scissors get three snaps in a circle, that’s my word. I suppose they’ll cause carpal tunnel, but what doesn’t, these days? Not much, I’ll tell you that. So will designer Efrat Gommeh.

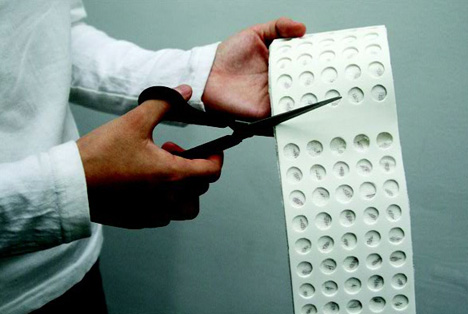

And don’t forget the bonus concept!

This little thing fits over your fingers so that when you make the “snip snip” scissors motion, you actually are using a scissors. Very elegant. Then, as a bonus design, Gommeh presents this “Folding Scissors” which turns from a 2-D item into a 3-D: origami for the destroyers of paper.

Designer: Efrat Gommeh

Coffee Addict Writes About Tea

The good thing about YD is that you get to cover stuff that you may not really enjoy, but heck if it’s a great design, why not share it with others. For instance many of you readers must be addicted to your java to get charged, but will that stop you from appreciating Enso Tea Percolator? Keeping with the traditional sensibilities of brewing the perfect cuppa, this three-piece tea percolator works pretty much like the moka espresso pot.

Designer: Jeffrey S. Engelhardt

Here’s how to make your fix:

Water in the bottom cup boils over a stove and rises up to the mid-section. This section also acts like a filter and is the place you keep the tealeaves. After you’re done with the brewing, just pour the drink straight up from Enso.

You won’t scorch your hands dears, cause the whole this is wrapped with a classy piece of wood.

Glass and wood is a neat combo, but it doesn’t guarantee a tasty cuppa tea!

Wicked! Try some espresso then!

Greening up

There’s this whole movement about bringing back nature into the concrete jungles we’ve built in the past 100 years but this is probably the most direct yet indirect way of doing it. Those painted line dividers we see everywhere serve a huge purpose but in an attempt to humanize and naturalize them, designer Ji-Hye Koo covers them with Nature On A Tape - essentially a pre-potted strip of grass that’ll grow with no effort. It’s sculptural and 3-dimensional but who’s gonna trim it tho?

Designer: Ji-Hye Koo

A Tea pot for making tea

…Short and stout, This is my handle and This is my spout.

When the tea is ready the thermochromic technology comes into play.

Watch me blush and change my colors all the way!

A badass attempt at poetry, but anyways the point is, the Creativi*tea Kettle is an effort to hype up the mundane chore of making tea and adding color to the kettle by including the temperature-sensitive aspect to it.

Cold = darker shade of red; Hot = increasingly luminescent red.

Designer: Sarina Fiero

Aqua, Hydra or Simply Water; It Needs To Be Clean

I don’t think I need to highlight the importance of clean drinking water to you elite crowd, but it is a major issue in many developing countries and war-torn zones. When designer Martin Bolton conducted a survey of the potable water that most rural houses in South Africa used, he was appalled at the quality and decided to do something about it. He devised an ingenious Potpaz Ceramic Filter system that is aimed at being a low cost water treatment device optimally suited to South African rural conditions.

Trying to keep the authenticity of the explanation of its working, here is what Martin has to say about the filter’s working:

Operation of the filter unit

The ceramic filter element is filled with water to be filtered, the water then saturates the ceramic filter element and slowly filters through the pores at a rate of between 1.5 to 2.5 liters per hour, provided the filter is kept full (as stated on the leaflet received from the existing filter element manufacturers). The filter needs the weight of the unfiltered water in the element to create sufficient pressure to push the water through the pores. The water filtering through the filter element drips into the receptacle where it is stored, ready for consumption. Users’ tap water from the plastic spigot attached through the receptacle wall. The covering lid prevents insects and dust from getting into contact with the filter element.

It has been shown that the filter element is able to improve the health related microbial quality of the water by means of the action of filtration. Effectiveness of the filter element, with regards to disinfection, can be increased with the application of colloidal silver to the filter element.

Colloidal silver is an effective antibacterial water treating agent in the form of tiny silver particles suspended in liquid. It is a disinfectant that prevents bacterial growth in the ceramic filter and assists in inactivating the bacteria in the filter. It is applied to the Potpaz filter in the form of a painted-on solution, or by dipping (after the firing process) thereby allowing the solution to soak into the porous ceramic filter where it remains. A study indicates that after 15 years in operation, the colloidal silver is still effective in the ceramic filter. The only routine maintenance of the filter components is as follows: The filter element needs to be scrubbed and rinsed once the flow-rate decreases considerably (possible once a month), and the inside of the receptacle needs to be cleaned with soap and water once a month.

Designer: Martin Bolton

Hope it does help to Team 7!

3D glasses

3D TV glasses make the movie or television show you’re watching look exponentially more real - with objects flying off the screen and careening in your direction, and creepy characters reaching out to grab you. Wearing 3-D glasses makes you feel like you’re a part of the action – Good times

Advances in 3D cinema and TV have advanced dramatically in recent months, but the technology is still over decade away from ditching those dodgy glasses that reduce us to looking like time lords from the 80’s. That’s a whole ten years of not looking very cool. Bad times.

Designer Chris Nobles solves this by creating something chic and retro. These wireless sunglasses have infared sensors in the logo area which communicate to the TV its location. The left and right lens are configured to give two opposing images generating the 3D effect.

Designer: Chris Nobles for HJC Design

Pain in the back

Thanks to my husband’s persistent back problems, I have become a second hand expert when it comes to the various methods to alleviate back pain. To make the back muscles strong, regular exercise, stretching, maintaining correct posture and Yoga helps a lot. For the moment when a spasm occurs, doctors usually advice muscle relaxing creams, compresses or painkillers. However sometimes indulgent contraptions like this VertaBrate massager may offer temporary relief.

The VertaBrate focuses on areas where the spinal nerves begin to permeate through the back and aims at diminishing the amount of discomfort that spawns at the beginning of these spinal nerves. It bends over the shoulders and clings to the body using sticky pads. The sticky arms embed four vibrating nodes that facilitate deep massage. Like I mentioned before, that sometimes doctors advice compresses to alleviate the pain, so depending upon what you have been advised, the VerteBrate can be popped into the freezer or microwave for temperature therapy.

From my experience in tackling back-related problems, the only mantra one should really follow is regular exercise and moderation in activities.

Designer: Jacob Ballard

2009年4月25日星期六

PP材料

pp材料

聚丙烯

PP材料概述:

PP塑料,化学名称:聚丙烯

英文名称:Polypropylene(简称PP)

比重:0.9-0.91克/立方厘米 成型收缩率:1.0-2.5% 成型温度:160-220℃

PP为结晶型高聚物,常用塑料中PP最轻,密度仅为0.91g/cm3(比水小)。通用塑料中,PP的耐热性最好,其热变形温度为80-100℃,能在沸水中煮。PP有良好的耐应力开裂性,有很高的弯曲疲劳寿命,俗称“百折胶”。PP的综合性能优于PE料。PP产品质轻、韧性好、耐化学性好。PP的缺点:尺寸精度低、刚性不足、耐候性差、易产生“铜害”,它具有后收缩现象,脱模后,易老化、变脆、易变形。

日常生活中,常用的保鲜盒就是由PP材料制成。

成型特性:

1.结晶料,吸湿性小,易发生融体破裂,长期与热金属接触易分解.

2.流动性好,但收缩范围及收缩值大,易发生缩孔.凹痕,变形.

3.冷却速度快,浇注系统及冷却系统应缓慢散热,并注意控制成型温度.料温低温高压时容易取向,模具温度低于50度时,塑件不光滑,易产生熔接不良,流痕,90度以上易发生翘曲变形

4.塑料壁厚须均匀,避免缺胶,尖角,以防应力集中.

PP 的工艺特点

PP在熔融温度下有较好的流动性,成型性能好,PP在加工上有两个特点:其一:PP熔体的粘度随剪切速度的提高而有明显的下降(受温度影响较小);其二:分子取向程度高而呈现较大的收缩率。

PP的加工温度在200-300℃左右较好,它有良好的热稳定性(分解温度为310℃),但高温下(270-300℃),长时间停留在炮筒中会有降解的可能。因PP的粘度随着剪切速度的提高有明显的降低,所以提高注射压力和注射速度会提高其流动性,改善收缩变形和凹陷。模温宜控制在30-50℃范围内。PP熔体能穿越很窄的模具缝隙而出现披锋。PP在熔化过程中,要吸收大量的熔解热(比热较大),产品出模后比较烫。PP料加工时不需干燥,PP的收缩率和结晶度比PE低。

聚丙烯(PP)性能概述与横向比较

PP与其它几种主要的通用塑料的性能比较

塑料种类 PP PE PVC PS ABS

密度 最小 小于水 较大 略高于水 略高于水

刚性 较好 差 好 好 好

收缩率 一般 差 好 好 好

韧性 低温下差 好 差 差 好

强度 较高 低 较高 高 高

耐热性 好 一般 差 较差 较差

化学稳定性 好 好 好 好 好

耐候性 差 差 一般 一般 较差

毒性 无毒 无毒 可以无毒 无毒 无毒

粘合剂粘合 差 差 好 一般 一般

热合性 一般 好 一般 一般 一般

成型加工性 好 好 麻烦 好 好

1、密度:PP是所有合成树脂中密度最小的,仅为0.90~0.91g/cm3,是PVC密度的60%左右。这意味着用同样重量的原料可以生产出数量更多同体积的产品。

2、力学性能:PP的拉伸强度和刚性都比较好,但冲击强度较差,特别是低温时耐冲击性差。此外,如果制品成型时存在取向或应力,冲击强度也会显著降低。虽然抗冲击强度差,但经过填充或增强等改性后,其机械性能在许多领域可与成本较高的工程塑料相竞争。

3、表面硬度:PP的表面硬度在五类通用塑料中属低等,仅比PE好一些。当结晶度较高时,硬度也相应增加一些,但仍不及PVC、PS、ABS等。

4、热性质:在五大通用塑料中,PP的耐热性是最好的。PP塑料制品可在100℃下长时间工作,在无外力作用时,PP制品被加热至150℃时也不会变形。在使用成核剂改善PP的结晶状态后,其耐热性还可进一步提高,甚至可以用于制作在微波炉中加热食品的器皿。

5、耐应力开裂性:成型制品中残留有应力,或者制品长时间在持续应力下工作,会造成应力开裂现象。有机溶剂和表面活性剂会显著促进应力开裂。因此应力开裂试验均在表面活性剂存在下进行。常用的助剂为烷基芳基聚乙二醇。试验表明PP在表面活性剂浸泡时的耐应力开裂性能和在空气中一样,有良好的抵抗能力,而且PP的熔体流动速率越小(分子量越大),耐应力开裂性越强。

6、化学稳定性:PP的化学稳定性优异,对大多数酸、碱、盐、氧化剂都显惰性。例如在100℃的浓磷酸、盐酸、40%硫酸及其它们的盐类溶液中都是稳定的,只有少数强氧化剂如发烟硫酸等才可能使其出现变化。PP是非极性化合物,对极性溶剂十分稳定,如醇、酚、醛、酮和大多数羧酸都不会使其溶胀,但在部分非极性有机溶剂中容易溶解或溶胀。

7、气密性(气体阻隔性):PP对氧气、二氧化碳和水蒸汽都有一定的透过性,比起尼龙(PA)和聚酯(PET)都有明显差距,对于高阻隔性塑料,如PVDC、EVOH等就差得更多了。但与其它非塑料材料相比其气密性还是相当好的。通过添加阻隔性材料或在表面涂敷阻隔性塑料,可以大大提高其气密性。

8、老化性能:PP分子中存在叔碳原子,在光和热的作用下极易断裂降解。未加稳定剂的PP在150℃下被加热半小时以上,或在阳光充足的地方曝晒12天就会明显变脆。未加稳定剂的PP粉料在室内避光放置4个月也会严重降解,散发出明显的酸味。在PP粉料造粒之前加入0.2%以上的抗氧剂可以有效地防止PP在加工和使用过程中的降解老化。抗氧剂分为游离基链反应终止剂(也称主抗氧剂)和过氧化物分解剂(也称辅抗氧剂)两大类,主、辅两类抗氧剂的合理配合,将会发挥良好的协同效果。目前推荐使用的B215抗氧剂就是主抗氧剂1010(酚类)和辅抗氧剂168(亚磷酸酯)按1:2的比例复配而成的。为防止光老化需要在PP中加入紫外线吸收剂,它可将波长290~400nm的紫外线吸收激化转化为没有破坏性的较长波长的光线。对于埋在土壤中或在室内避光使用的PP塑料制品仅加入主辅抗氧剂即可,无须加入紫外线吸收剂。

9、电性能:PP属于非极性聚合物,具有良好的电绝缘性,且PP吸水性极低,电绝缘性不会受到湿度的影响。PP的介电常数、介质损耗因数都很小,不受频率及温度的影响。PP的介电强度很高,且随温度上升而增大。这些都是在湿、热环境下对电气绝缘材料有利的。另一方面PP的表面电阻很高,在一些场合使用必须先进行抗静电处理。

10、加工性能良好:PP属于结晶型聚合物,不到一定温度其颗粒不会熔融,不像PE或PVC那样在加热过程中随着温度提高而软化。一旦达到某一温度,PP颗粒迅速融化,在几度范围内就可全部转化为熔融状态。PP的熔体粘度比较低,因此成型加工流动性良好,特别是当熔体流动速率较高时熔体粘度更小,适合于大型薄壁制品注塑成型,例如洗衣机内桶。PP在离开口模后,如果是在空气中缓慢冷却,就会生成较大的晶粒,制品透明度低。果是在水中急冷(如下吹水冷法制薄膜),PP的分子运动被急速冷冻,不能生成晶体,此时的薄膜就是完全透明的。PP的成型收缩率是比较大的,达到2%以上,远远大于ABS塑料(0.5%)。PP的成型收缩率可以随着添加其它的材料的种类及多少有所变化,这在制作具有配合尺寸的注塑制品时需认真加以考虑。